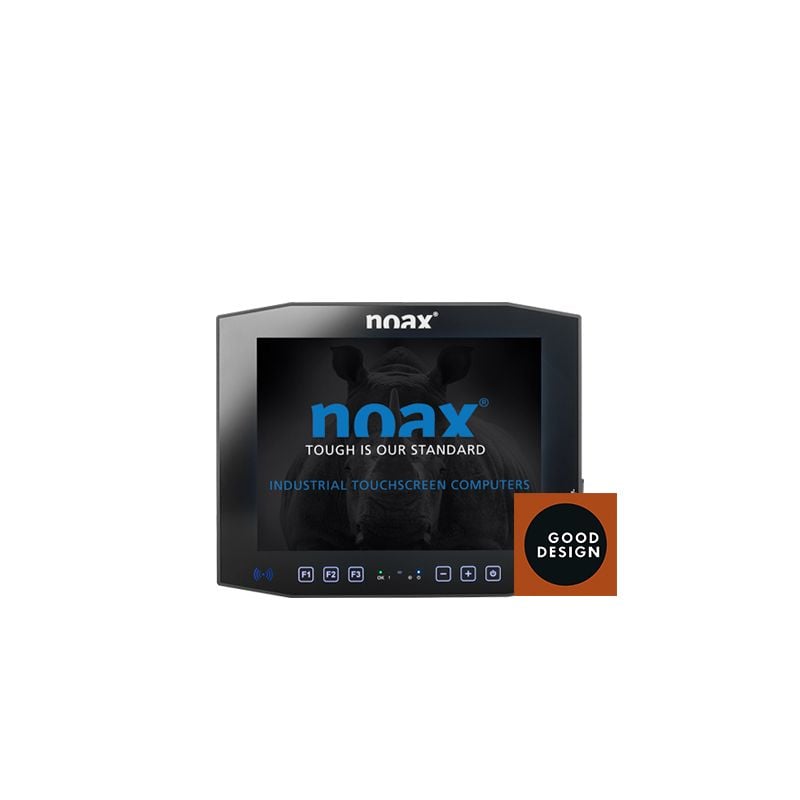

noax Housing Design and Hygienic Design

good design award winner

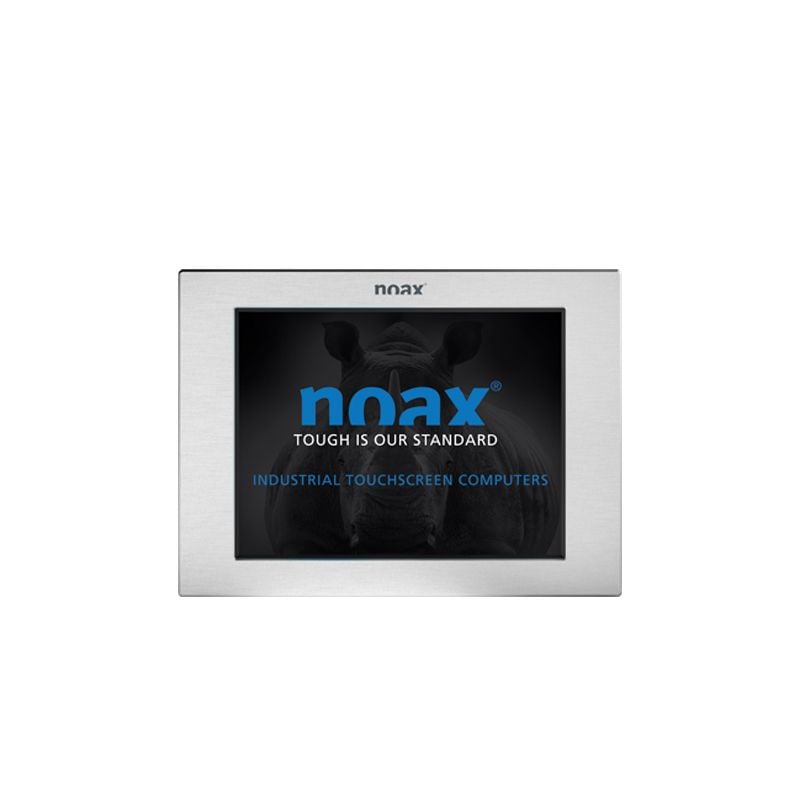

Hygienic Design

In hygiene-critical production environments, the avoidance of contamination of the end product is a key requirement. In the food sector in particular, the catchphrase “hygienic design” is often used when it comes to the design of production systems.

With regard to industrial computers, “hygienic design” is to be understood as meaning, in particular, the cleaning-friendly design of the housing, which includes the IP protection and the avoidance of undercuts and hygienic seals. However, the aspects of glass breakage and the resistance of the materials used also play a role that should not be underestimated in the development of HAACP and IFS compliant industrial computers for the food industry.

When designing industrial computers for the food sector, numerous criteria must be met with regard to the housing design, including the avoidance of dead spaces and undercuts and easy-to-clean, smooth surfaces.

Only with a hygienic housing design can the risk of bacteria build-up be reduced to a minimum and also facilitate daily cleaning of the devices.

Hygienic design – materials

Choosing the right materials poses major challenges for many manufacturers. For example, food-safe industrial seals are absolutely necessary in hygiene-critical environments, although 100% tightness must still be ensured. Noax therefore only uses food-safe industrial seals with AUTO-FIT properties in the hygiene sector. These also defy strong environmental influences and were developed to withstand multiple daily cleaning with boiling water and high-pressure cleaners (IP69K – externally certified) without any problems.

The V2A stainless steel housing with industrial finishing touches on the one hand meets hygienic requirements (HACCP) through the antimicrobial effect and on the other hand is characterized by the surface insensitivity of the stainless steel, which means that the surface is not changed by cleaning agents customary in the industry.

In practice, this means for you that by using noax industrial computers, the combination of easy cleaning and durable material ensures uncompromising hygiene and reduces the risk of food contamination to a minimum.

Test us out at your facility to see how tough a noax computer actually is!

Phone: (704) 992 1606 - Fax (704) 992 1712 - info-na@noax.com - hotline-na@noax.com

Call-Back-Service

Fill out the form and we will call you back!

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationSign up for our newsletter