Wide range of industry applications

Agriculture

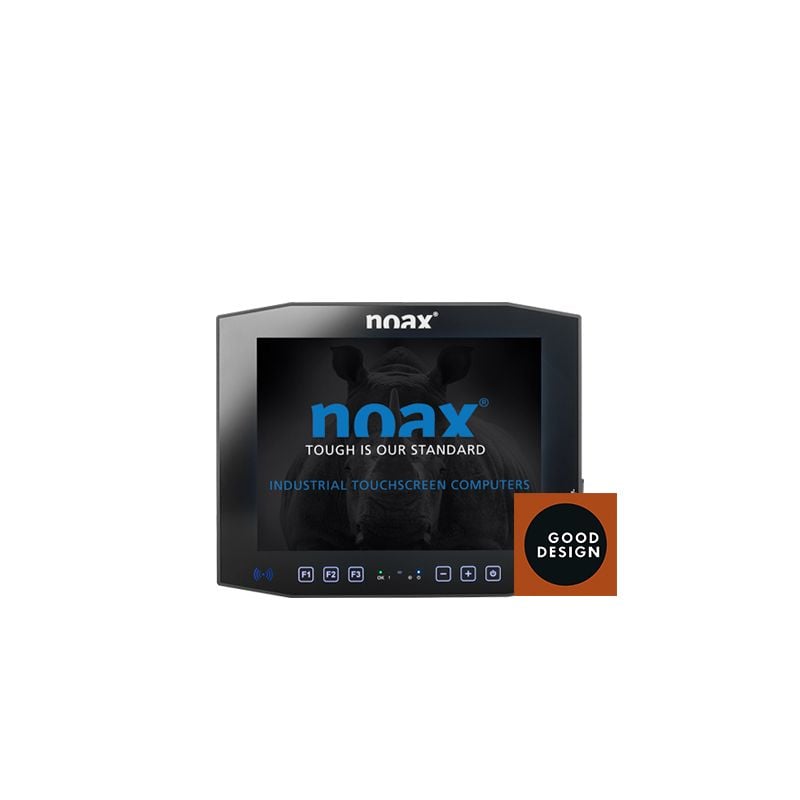

With the application of IIoT (Industrial Internet of Things) solutions, the agriculture industry is able to increase efficiency, reduce operating costs and pave the way for future growth. Access to real-time data and analytics helps harvesters plan and predict future crop yields, lower production costs through process automation, capture data while in the field, communicate with farmers, and track livestock. noax Technologies provides customizable computers designed for use in extreme environments that communicate with other connected systems and IIoT devices in the field to record data. Our rugged IIoT computers have a durable and completely sealed construction with IP65 to IP69K ingress protection certifications. This heavy duty technology hardware has unmatched resistance to continuous shocks and vibrations, moisture, humidity, dirt and strong chemicals, our ruggedized PCs.

- Farming Machinery

- Harvesting Vehicles

- Machine Control

- Production

- Inventory Management

- Smart Farming

Food & Beverage

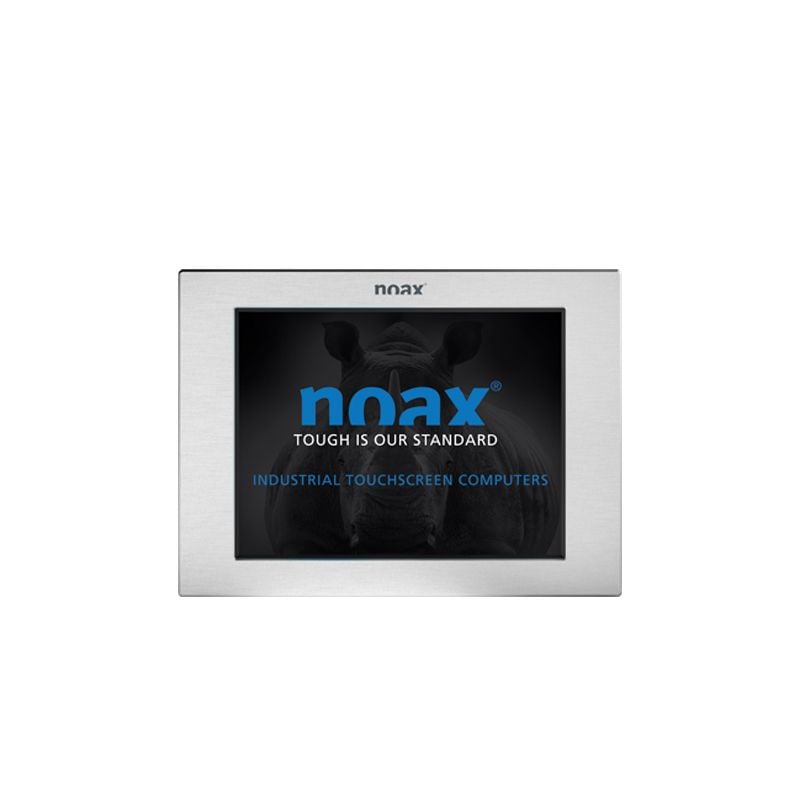

Computers are a vital part of all production processes. Food and beverage manufacturers must ensure the quality and safety of the food products they produce. By providing smart manufacturing solutions to enhance your food and beverage operations, we can help you solve your biggest challenges. We provide solutions to optimise workflow, quality assurance and improve overall production management with accessibility to relevant data, process and external machine automation, real-time reporting and process visualization. Food and beverage production facilities must meet strict hygienic regulations and undergo daily cleaning and sterilization. Production equipment must have the ability to withstand high pressure hoses and strong disinfectants that are used during sanitation processes to kill harmful bacteria. noax’s line of stainless steel waterproof computers can handle the same sanitation processes as all other food processing equipment on the plant floor. They are designed for the harshest hygienic environments such as those in food processing and wet applications.

- Meat, Poultry & Seafood

- Bakery & Confectionary

- Dairy & Beverage

- Convenience & Frozen

- Pet Care

- Bottling & Packaging

Logistics & Transportation

During the transport of goods, inventory management and real-time communication are vital in ensuring accuracy and efficiency in logistics operations, even in the toughest environments. noax’s rugged logistics computers are designed to reliably and flawlessly operate in the most challenging applications and weather conditions. noax industrial in-vehicle computers are ingress-proof and feature a wide operating temperature range, real-time communications in the most remote locations, advanced impact and vibration resistance and specially designed power and safety features for in-vehicle installations. Improve quality control and seamlessly support all your intralogistics processes with real-time communication, increased efficiency and accuracy in order picking, traceability, data acquisition, production automation, inventory management, recording data and process visualization while directly on site.

- Cranes & Construction Vehicles

- Heavy Duty Vehicles & Machinery

- Intermodal Transshipment & Container Yards

- Shipyards & Railway

- Cold & Freezer Storage

- Outdoor Kiosks & Distribution Yards

Industrial Automation

Industry 4.0 refers to the production processes in which people, machines and tools work in real time in an intelligently linked network at any location. The use of industrial computers to automate manufacturing processes can enhance virtually every step involved in manufacturing processes. This advancement in industrial processes puts advanced technologies to use directly on the manufacturing floor for data collection to increase predictive analytics and artificial intelligence. Industrial computers allow you to have more control in the implementation and progress of processes with less hands-on work and more efficiency and accuracy. Computer systems can communicate and control each other with reduced human involvement in real-time. All-in-one industrial PCs support this modernization in the manufacturing infrastructure. The full process from design to installation on machinery can be combined into one IT landscape.

- HMI Automation

- Data Acquisition

- Machine Control

- Data Visualization

- Centralized Management

- Real-time Mobile Access, Anytime, Anywhere

Manufacturing

The longest lasting ruggedized computers are built to survive the most challenging conditions and run reliably at peak performance in manufacturing environments, withstanding dust, dirt, moisture, extreme temperatures, sparks, strong impact and continuous vibrations. Our manufacturing computers are fully sealed, IP65 – IP69K certified for ingress protection and built from the ground up using only the highest quality industrial components. The challenging environments in production and manufacturing can be detrimental to computer hardware. With the revolution of Industry 4.0 and IIoT in the manufacturing industry, advanced technology can be used directly on the production floor for improved process automation, data collection, increased predictive analytics and artificial intelligence.

- Vehicle Manufacturing

- Packaging & Bottling

- Rubber & Plastics Production

- Cement Production

- Civil Engineering

- Smart Factory Systems & Industry 4.0

Metals

The process of melting metals produces extreme temperatures requiring devices built to withstand limits that exceed typical expectation. Metal foundries and fabrication facilities need a higher level of durability in industrial hardware than typical manufacturing facilities. Metal foundries are some of the harshest environments imaginable with molten metal, grinding, sparks, condensation, oil, shavings, dust, more dust, and did I say dust? Ruggedized computing equipment is essential for smooth and efficient operations in the extremely demanding environments of metalworking. Ingress protection is especially important. HMI computers used in this type of environment should be industrial-grade, completely sealed, and protected from the possibility of dust and liquid getting inside the device. The versatile designed rugged industrial HMI computers enable it to be mounted and placed right next to machinery.

- Machine Control

- Process Control & Visibility

- Real-time Communication

- On-site Monitoring Of Operations

- Inventory Management & Traceability

- Production Automation

Mining & Tunneling

Indoor and outdoor facilities that are involved in the drilling, extraction or refining of materials removed from the earth are typically in challenging environments that have intense shock and vibration, high concentrations of dust, extreme temperatures, high humidity, and significant wear and tear on equipment. This industry needs reliable wireless IT hardware to communicate in real-time from the job site for monitoring operations, process control, synchronizing data, machine control and precise quality control. With over 25 years of experience in the research and development of rugged industrial computers, noax Technologies provides completely sealed and extremely durable IT hardware with integrated resistive touch panels to ensure simple and reliable operation. The 304 stainless steel or cast aluminum housing is IP65 rated for ingress protection on all sides of the device.

- Tunnel Boring Machinery

- Civil Engineering

- Industry 4.0 Machine Control

- Rock Engineering & Excavation

- Underground Construction

- Drilling Rigs

Pharma & Biotech

In the pharmaceutical and biotechnology industries, hygiene is essential. The entire facility must be cleaned daily with intense high pressure wash downs using hot water and aggressive chemical disinfectants to keep a clean antibacterial production facility. Pharmaceutical facilities must be in compliance with strict regulatory and hygienic requirements. The Industrial Revolution has changed the infrastructure of industries like manufacturing, food processing, transportation and logistics. Now, the time has come for the pharmaceutical and biotechnology manufacturing industries to find a solution to increase quality, connectivity, productivity, profits, and decrease waste and risk to stay competitive. Pharma 4.0 (Biopharma 4.0) is the term used to describe the Industry 4.0 term coined for the Pharmaceutical and Biotechnology industry. Smart manufacturing technology enables continuous, real-time monitoring of all manufacturing processes. Thus, increasing visibility, traceability and providing real-time digital records for quicker decision making, process improvement, and risk prevention. With increased visibility, you will not only be able to find new opportunities for improvements, you can also correct problems before they occur. By automating processes, Pharma 4.0 computer systems can help pharmaceutical manufacturers avoid significant downtime, increase profit and stay competitive.

- Biotechnology Manufacturing

- Pharmaceutical Manufacturing

- Batch, Process & Machine Control

- Traceability and Quality Assurance

- Bottling and Packaging

- Data Synchronization & Software Compatibility

Warehouse

Your warehouse is the central hub for your products and if the supply chain management procedures are not efficiently operating, you could be sacrificing time, quality assurance, retention and money. A minor mistake in the warehouse or distribution center can cause significant consequences throughout the entire supply chain. By integrating rugged computing in warehouse automation, not only will you increase efficiency and accuracy, streamlining processes will help future-proof your business. noax Technologies understands the challenges in the supply chain portfolio and provides custom IT solutions based on your unique applications. We will fully evaluate your physical environment, operation procedures and IT infrastructure to ensure convenience, requirements, and seamless integration. noax offers all-in-one solutions built to survive the toughest conditions for in-vehicle mounting, industrial HMI workstations and outdoor computers. Designed from the ground up, our devices are engineered for sustainability in the most demanding warehouse environments, lasting for at least 5 to 10 years without failure.

- Forklift Automation

- Order Picking and Data Entry

- Packaging & Shipping

- Cold and Freezer Storage

- Inventory Management

- Conveying and Sorting

Marine

Conditions at sea can be harsh, with splashing salt water, continuous rocking and extreme temperatures. Using ruggedized industrial technology on maritime vessels, specifically on-board fishing vessels helps to automate and monitor processes. Our rugged computers are custom built from the ground up and guaranteed to run reliably for years in the toughest environments. Marine PCs are able to withstand severe shock and vibrations, significant temperature changes, humidity and full submersion. noax marine computers are certified in accordance with IP65 to IP69K and NEMA 4X and NEMA 6 protection standards. Completely sealed on all sides and ingress-proof, these waterproof computers prevent dust, debris and water from damaging the devices.

- On-Shore and Off-Shore

- Monitoring and Surveillance

- Navigation and Process Control

- Data Synchronization and Traceability

- Shipbuilding

- Maritime Transshipment and Container Handling

Phone: (704) 992 1606 - Fax (704) 992 1712 - info-na@noax.com - hotline-na@noax.com

Call-Back-Service

Fill out the form and we will call you back!

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationSign up for our newsletter